Insights

Metalworking

Industry

Handling oil recovery efficiently

“What better way could there be to protect the environment and save costs?” remarks Markus Korta, Otto Gantner Plant Manager at Rheinhausen, where the CEPA FLEXOMAT is used for efficient de-oiling of metal chips.

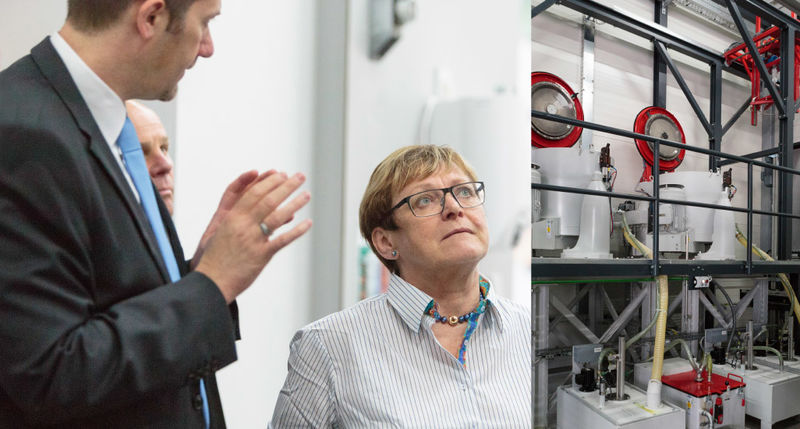

On site at Otto Ganter GmbH & Co. KG - A leading manufacturer of handles and standard parts, and a long-standing CEPA customer.

Two high-performance centrifuges of the GZ series are in use at the Rheinhausen plant, separating metal chips from the oil used as coolant and lubricant in the automatic lathes.

Since the FLEXOMAT went into operation, the process of recovering the precious aluminium, stainless steel and steel chips has been as profitable as it has been smooth. Recycling the cleaned metal residue brings in hard cash, as does recovering oil from centrifuging, because it can then be returned to the production process and minimises the need for purchases of fresh oil.

A group of prospective FLEXOMAT customers from Sweden is viewing the system in action at Ganter and is impressed at its efficiency. “In the FLEXOMAT, the chip stays in the same container throughout the entire process, from the moment it is formed. Individual centrifuging times that depend on the material are possible in this system. All manner of chip shapes, including endpieces and coarse particles, are centrifuged straight off without any further crushing or grading. Drip-free and always separated,” explains CEPA sales member Bernd Leibold. The FLEXOMAT is tailored individually to requirements on the ground. A successful concept for using raw materials economically based on engineering expertise stretching back more than 90 years.

A doubly profitable economic factor

“The new plant is not yet running at full capacity. At the moment we get through 300 litres of oil per day. At a cost of EUR 2.50 per litre, that means Ganter is already making a quite appreciable saving of EUR 750 every day,” explains Markus Korta. The oil can be returned straight to the processing machine. The de-oiling system is rapidly paying its way and has a very long operating life.

More modern processing machines require highly pure oil. Here too, the oil recovered by the FLEXOMAT system can be used. Just one intermediate step is needed: CEPA cleaning centrifuges perform the final cleaning of the recovered oil.