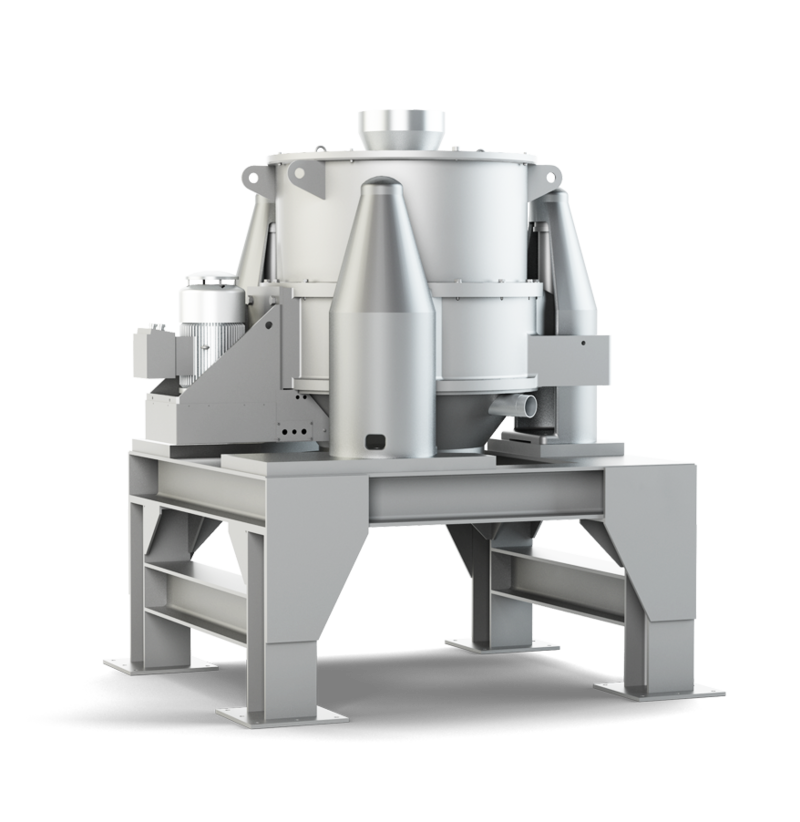

The power pack. Stroke after stroke, dry chips.

The continuously operating de-oiling centrifuge KSE is suitable for all kinds of metal chips, grinding sludge and shredder material. The centrifuge contains a hydraulically driven lifting base that periodically discharges the chips upwards over the slotted-hole screen. The centrifuge is filled continuously with chips by feed conveyors. The fixed lifting intervals produce very consistent de-oiling results.