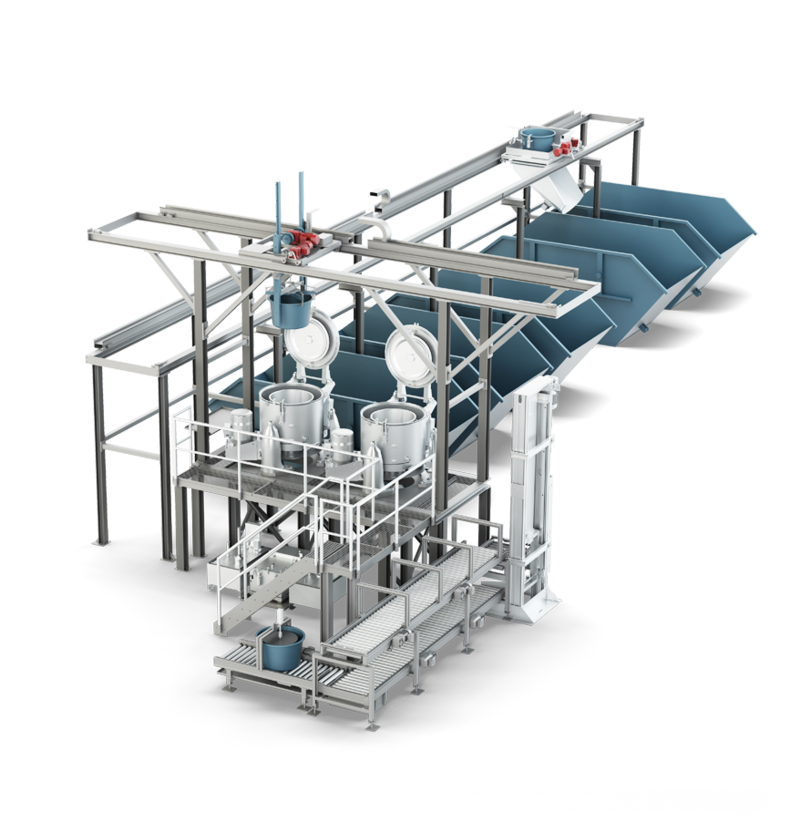

Manual centrifuges as a modular system

The system that grows along with your requirements.

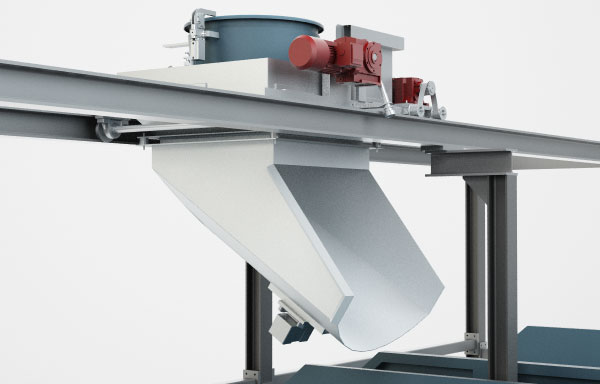

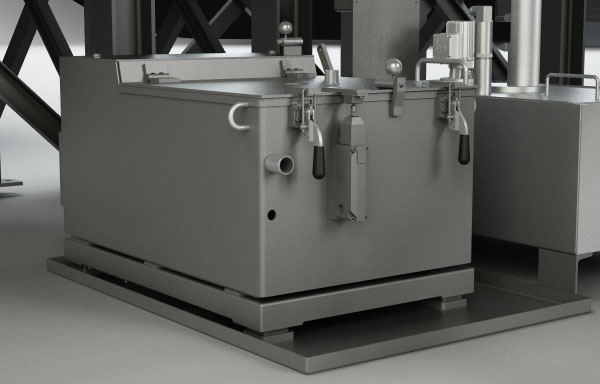

With the FLEXOMAT as a modular system, CEPA offers customers the option of a custom-planned and built system for processing a variety of chip types and parts. Tailored to your needs, easy to operate, reliable and individually extended. The FLEXOMAT system unites the flexibility of a manual centrifuge with an efficient, fully automated process.

CEPA Flexomat the classical from CEPA Centrifuges.

The chip disposal system that grows with your requirements. Expandable to almost any number of containers and types of chips. The system can be extended like a kit. Semi-automatic at the beginning to dispose of your chips fully automatically in the later course.

In the FLEXOMAT, all metal types can be de-oiled separately and drip-free in a single system, without the need for transferring. Different types of chip are not mixed, because the chip stays in the same container throughout the entire process, from the moment it is formed. The system’s specific design renders any elaborate preparation of the chips, such as crushing or screening, entirely unnecessary. Different chip shapes, including endpieces and coarse parts, are just centrifuged straight

off without any further crushing or grading. The centrifuging time always depends on the material in question. The thoroughly separated and recovered coolants and lubricants can be returned to the production process.