High Speed. Flexible. Resistant.

High-Speed Tubular Centrifuges are mainly used to separate smallest particles from fermenter suspensions. Suspension is fed into the rotor from below while the centrifuge is running. The components of the suspension are stratified in the rotor according to their density. While the liquid is continuously discharged via the discharge trays, the solid remains in the rotor and is harvested manually.

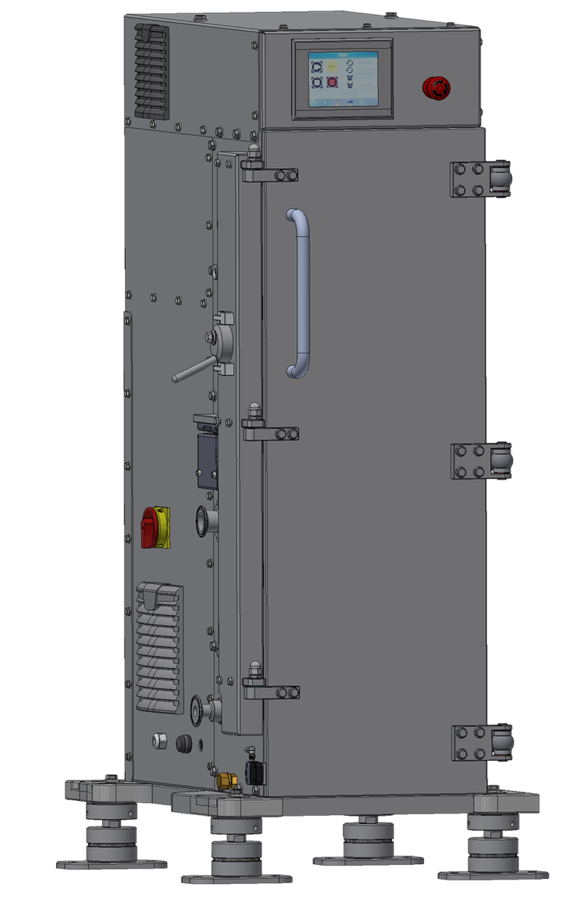

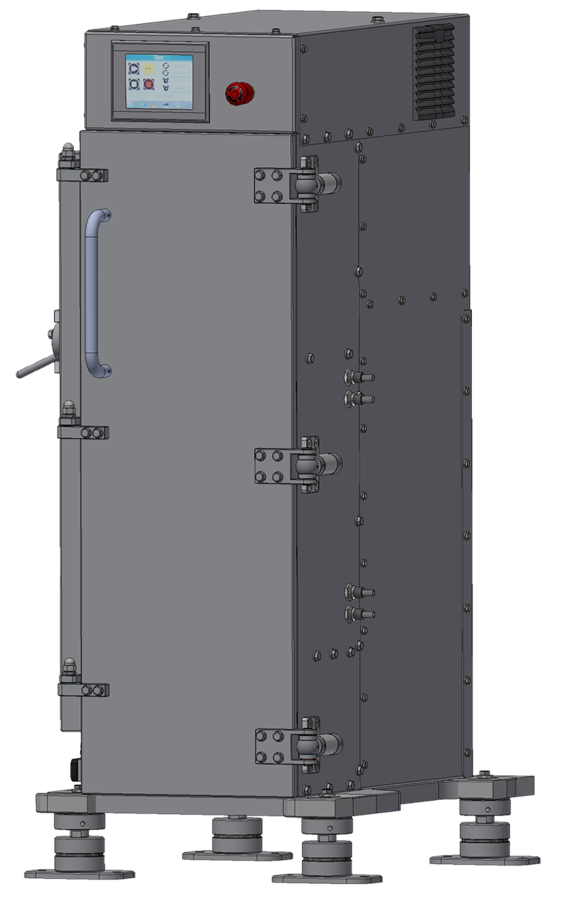

This centrifuge is currently available as a basic machine in a cast housing, in a GMP-compliant stainless steel version (GP), as an explosion-proof version (GP ex.), also in stainless steel and in a CIP version (GE).

This type of centrifuge can also be installed in a trailer e.g. for water testing, which can be used anywhere. We are happy to support you in planning the trailer using our centrifuge.